– RF, Microwave, High Speed Digital PCBs

RF and microwave PCBs are typically built using advanced composites with specific characteristics for dielectric constant Dk, loss tangent Df, and coefficient of thermal expansion (CTE).

High frequency circuit materials with a low stable Dk and loss tangent Df allow for high speed signals to travel through the PCB with less impedance than standard FR-4 PCB materials. These materials can be mixed in the same stack-up for optimal performance and economics.

Our supplier choice for a RF and Microwave PCBs material is isola – a global material sciences company focused on designing, developing, manufacturing and marketing copper-clad laminates and dielectric prepregs used to fabricate advanced multilayer printed circuit boards. Isola high-performance materials are used in a diverse range of electronic end-markets including applications in computers, networking and communications equipment, high-end consumer electronics, as well as products designed for use in the advanced automotive, aerospace, military and medical markets.

The company invests in research and development to create industry-leading products formulated to meet the most demanding performance requirements of its customers, the printed circuit board fabricators, and the designers and original equipment manufacturers (OEMs) they serve. The global footprint includes manufacturing facilities and research centers located in Europe and the United States.

Competitive matrix

(for materials we have available in stock)| Isola Product | Dk @ 10GHz | Df @ 10GHz |

|---|---|---|

| I-Tera® MT40 RF | 3.38 | 0.0028 |

| I-Tera® MT40 MW | 3.45 | 0.0030 |

| Competitive material | Dk @ 10GHz | Df @ 10GHz |

|---|---|---|

| Rogers RO4003 | 3.38 | 0.0027 |

| Taconic TLC-338 | 3.38 | 0.0034 |

| Rogers (Arlon 25N) | 3.38 | 0.0025 |

| Nelco NH9338 | 3.38 | 0.0025 |

| Nelco N9530-13RF | 3.38 | 0.0046 |

| Rogers RO4534 | 3.40 | 0.0027 |

| Nelco Meteorwave 1000 | 3.40 | 0.0040 |

| Rogers RO4350B | 3.48 | 0.0037 |

| Rogers RO4350BTX | 3.48 | 0.0034 |

| Rogers RO4835 | 3.48 | 0.0037 |

| Nelco NH9348 | 3.48 | 0.0037 |

| Nelco NH9350-13RF | 3.48 | 0.0055 |

RF, Microwave material available on stock:

| Thickness [mm] | Dk (2-20 GHz) | Df (2-20 GHz) | Tg (℃) | CTE in Z-Axis (ppm/℃) | Cu type VLP-2 | Cu thick. (μm) | Panel size [mm] |

I-Tera MT40 RF

| Laminate | 0.127 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 0.254 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 0.508 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 0.762 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 1.016 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 1.524 | 3.38 | 0.0028 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

I-Tera MT40 MW

| Laminate | 0.254 | 3.45 | 0.0030 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

| Laminate | 0.508 | 3.45 | 0.0030 | 200 | 290 | Rz=2 μm | 18/18 | 275x505 |

Prepreg

| PR2116 | 0.138 | 3.48 | 0.0031 | 200 | 290 | 59% resin content | 275x505 |

| PR1080 | 0.101 | 3.14 | 0.0022 | 200 | 290 | 73% resin content | 275x505 |

| PR1035 | 0.064 | 3.14 | 0.0022 | 200 | 290 | 73% resin content | 275x505 |

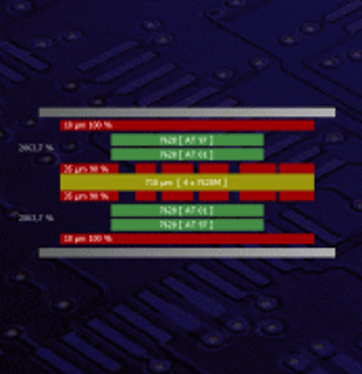

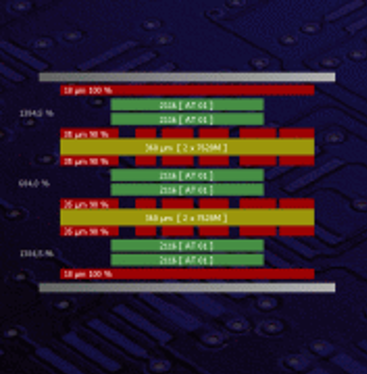

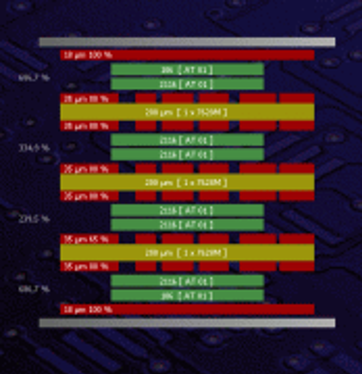

RF PCB Layer Stackup – “Pure Build” Versus “Hybrid Build”

A “Pure build” refers to a multilayer PCB material construction that is composed of the same type of material throughout the stackup.

A „Hybrid build“ could use a mix of Isola PCL370HR high performance material 180°Tg with high-frequency material Isola I-Tera MT40.

The reasons for using a hybrid construction in RF multilayer PCB designs are typically driven by cost, reliability, or electrical performance.

When designs feature a number of noncritical circuit layers, these can usually be built on the more cost-friendly PCL370HR material only using high-frequency RF materials on the critical circuit layers.

Hybrid construction is becoming more popular as technology evolves, but hybrids bring both benefits and challenges that need to be understood. Working closely with the PCB fabricator will ensure the best construction methodology that balances RF performance and PCB manufacturability.

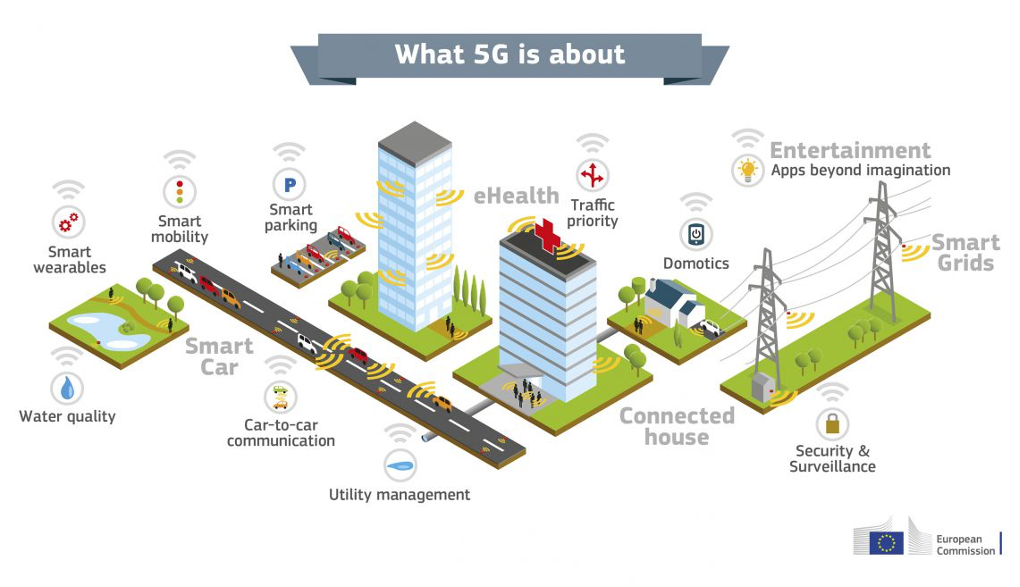

SQP International Towards 5G – Shaping our Europe’s digital future

The “fifth generation” of telecommunication systems, or 5G, will be one of the most critical building blocks of our digital economy and society in the next decade. SQP International has taken significant steps to participate in global developments towards this strategic technology.

High speed digital printed circuit boards are key components for devices processing or transmitting high data rates. Typical applications are IC test systems, 5G base stations, internet switches, IoT devices and high speed computing. These systems operate in many cases with data rates of 10Gbit/s or more.

Please select suitable material based on its specs and features – detailed material specification.

Maximum panel dimensions

| Double sided PCB | Multilayer PCB |

|---|---|

| 325 mm x 582 mm | 274 mm x 505 mm |

ML copper-clad laminates on stock

| Thickness (laminate thickness) |

Isola DE104 | Isola PCL370HR | |||||

|---|---|---|---|---|---|---|---|

| [mm] | Cu 18/18 | Cu 35/35 | Cu 70/70 | Cu 18/18 | Cu 35/35 | Cu 70/70 | Cu 105/105 |

| 0.075 | |||||||

| 0.100 | |||||||

| 0.125 | |||||||

| 0.150 | |||||||

| 0.200 | |||||||

| 0.300 | |||||||

| 0.360 | |||||||

| 0.410 | |||||||

| 0.460 | |||||||

| 0.560 | |||||||

| 0.610 | |||||||

| 0.710 | |||||||

| 0.900 | |||||||

| 1.000 | |||||||

Rigid copper-clad laminates on stock

| Thickness (overall thickness) |

Isola DE104 | Isola PCL370HR | |||||||

|---|---|---|---|---|---|---|---|---|---|

| [mm] | Cu 0/35 | Cu 18/18 | Cu 35/35 | Cu 50/50 | Cu 70/70 | Cu 18/18 | Cu 35/35 | Cu 50/50 | Cu 70/70 |

| 1.00 | |||||||||

| 1.20 | |||||||||

| 1.50 | |||||||||

| 2.00 | |||||||||

| 2.40 | |||||||||

| 3.20 | |||||||||

Prepregs on stock

| Isola DE104 | Isola PCL370HR | |

|---|---|---|

| Type | Pressed thickness [mm] | |

| 106 | 0.057 | 0.045 |

| 1080 | - | 0.065 |

| 2116 | 0.105 | 0.090 |

| 7628 | 0.197 | 0.172 |

| PL05 2116 | - | 0.110 |

| PL04 7628 | - | 0.198 |

| PL05 1080 | - | 0.070 |

Copper foils on stock

| Thickness [um] | Copper Foil |

|---|---|

| 5 | |

| 6 | |

| 12 | |

| 18 | |

| 35 | |

| 50 | |

| 70 | |

| 105 | |

| 140 |

| 106 | 48 µm | 46 µm | 48 µm |

| 1080 | 69 µm | ||

| 2116 | 109 µm | 97 µm | 99 µm |

| 106 | 48 µm | 46 µm | 48 µm |

Copper foils on stock

| Copper foil | |||

|---|---|---|---|

| Thickness [µm] | 312 x 380 mm | 312 x 512 mm | 312 x 600 mm |

| 5 | |||

| 9 | |||

| 12 | |||

| 18 | |||

| 35 | |||

| 50 | |||

| 70 | |||

| 105 | |||

| 140 | |||

Standard multilayer build-ups: